20. Biosolids and the need for Potash (1.72M)

pdf 1.72M

20. Biosolids and the need for Potash

Published March 2020

Biosolids (Sewage Sludge)

Biosolids (sewage sludge) provide valuable plant-available nutrients and have useful soil conditioning properties. They are subject to regulations which require that the application rates of specific heavy metals and their concentrations in soils are not exceeded, that disease risks to stock and humans are minimised and that applications should match the requirements of crops. Rates of applications are therefore important and so is the balance of nutrients. Water companies go beyond the regulations by agreement with stakeholders. Potential contaminants have been greatly reduced over the years by cooperation with industry, with their removal at source, and by legislation that has prevented the manufacture and sale of hazardous substances. Biosolids provide useful quantities of nitrogen and phosphate, but only modest amounts of potash and magnesium because these elements are quite soluble and are washed out in the treated water. Lime stabilised biosolids are a useful liming material.

Because most plant species require a greater total supply of potash than any other nutrient it is vital to complement biosolids with appropriate applications of potash fertiliser.

Typical nutrient content of biosolids

| DM | Nitrogen | Phosphate | Potash | Sulphur* | Magnesium | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % | total | available | total | available | total | available | total SO3 | total MgO | |||||||||||

| Digested cake | 25 | 11 | 1.1-2.2 | 11 | 5.5 | 0.6 | 0.5 | 8.2 | 1.6 | ||||||||||

| Thermally dried | 95 | 40 | 4-8 | 55 | 28 | 2.0 | 1.8 | 23 | 6.0 | ||||||||||

| Lime stabilised | 25 | 8.5 | 0.9-1.7 | 7 | 3.5 | 0.8 | 0.7 | 7.4 | 2.4 | ||||||||||

| Composted | 40 | 11 | 1.1-1.65 | 10 | 5.0 | 3.0 | 2.7 | 6.1 | 2.0 | ||||||||||

| Source: AHDB Nutrient Management Guide (RB209) | |||||||||||||||||||

| * For crop-available sulphur assume 10-20% (25% for grassland and winter oilseed rape) To convert kg/m3 to units/1000 gallons, multiply by 9. To convert kg/t to units/ton, multiply by 2. |

|||||||||||||||||||

At typical application rates matched to total nitrogen limits within NVZ’s, this would supply over 110 kg/ha available phosphate but just 12 kg/ha available potash.

Legislation

Biosolids recycling to agricultural land must comply with numerous pieces of legislation and best practice guidance, including:

- The Sludge (Use in Agriculture) Regulations 1989

- The Sludge (Use in Agriculture) (Amendment) Regulations 1990

- Code of Practice for Agricultural Use of Sewage Sludge (1996)

- The ADAS Safe Sludge Matrix (2001)

- Cross Compliance

- The Nitrates Regulations

- Codes of Good Agricultural Practice

- AHDB Nutrient Management Guide (RB209);

Best fertiliser practice

Nitrogen

Best fertiliser practice requires nitrogen (N) to be applied to an economic optimum level with timing matched to plant growth so that risk of N loss to the environment is minimised. Excess nitrogen carry-over should be avoided.

Protecting our Water, Soil and Air: A Code of Good Agricultural Practice for farmers, growers and land managers recommends a limit on the amount of total nitrogen to be applied in sludges and other organic manures to no more than 250 kg/ha/year.

More stringent limits apply in NVZs – at the field level it is not permitted to apply more than 170 kg/ha total N/year. This limit is the loading limit and applies as an average across the holding. It’s separate from the field limit of 250 kg/ha from organic manures. Also, full allowance should be made for crop-available nitrogen supply from biosolids when calculating how much inorganic fertiliser N (if any) a crop needs.

Phosphate and Potash

The principles are quite different to those for nitrogen.

Best practice requires the maintenance of acceptable levels of these nutrients in the soil on a long-term basis. Fertiliser applications should aim to raise soil phosphorus (P) and potassium (K) to such levels that no further economic response occurs, and then to maintain these levels in the soil by replacing the nutrients removed in harvested crops.

Soils should be analysed regularly, ideally every 3 to 5 years (at least every 5 years is a requirement of the Farming rules for Water 2018), to set and maintain a correct fertiliser policy. This can be done as part of a nutrient management plan.

At soil P Index 3 and above, phosphate additions (biosolids or fertilisers) should not exceed crop offtake over the rotation. For most crops no phosphate is recommended at Index 4 or above, but biosolids may be applied, taking care to minimise the risk of run-off, soil erosion or leaching.

| Soil P Index |

Maximum potential application of lime stabilised biosolids |

Maximum potential application of all other biosolid types |

| 0 / 1 / 2 | 250 kg/ha total N in any 12-month period | 250 kg/ha total N in any 12-month period |

| 3 | 250 kg/ha total N in any 12-month period – application 1 year in 4 on sandy soils and 1 year in 2 on all other soils | 250 kg/ha total N in any 12-month period – application 1 year in 2 on sandy soils |

| 4 | 250 kg/ha total N in any 12-month period – application 1 year in 5 on sandy soils and 1 year in 3 on all other soils | 250 kg/ha total N in any 12-month period – application 1 year in 4 on sandy soils and 1 year in 2 on all other soils |

| 5 and above | No application | No application |

|

Source: Biosolids Nutrient Matrix (2014) |

||

Nitrogen and potash balance

N and K are essential partners. If potash is limiting, the crop will not respond fully to nitrogen, penalising yields and product quality. Biosolids can provide large quantities of nitrogen which must be balanced with adequate potash to ensure its efficient use.

Inefficiencies of N uptake and use in the plant may result in significant losses of nitrogen if potash levels are deficient.

Visual symptoms of P and K deficiency

Visual symptoms in a crop cannot be relied upon to determine the adequacy of potash or phosphate supply. Deficiency symptoms are easily confused with other problems, frequently appear too late for damage to be prevented or may be totally absent despite yield and quality penalties.

The best way to ensure the maintenance of adequate soil fertility is to apply nutrients to replace those removed by cropping, and to monitor soil reserves by regular analysis every 3-5 years.

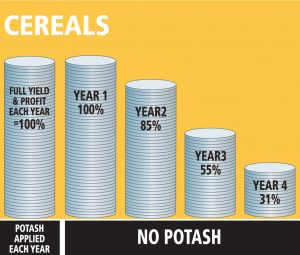

Potash and profit

Unlike many factors, potash fertility is within a farmer’s control and it is unwise to allow low reserves of this essential input to impact crop performance.

The penalty of inadequate potash will depend upon the soil type, the crop and the growing conditions. Even with so-called ‘less responsive’ crops such as cereals or grass the effects can be large.

Sulphur

Crops should be provided with a balanced supply of the major nutrients, including sulphur. As with readily-available nitrate, sulphate can be liable to loss through leaching. Therefore, as with nitrogen, economic optimum levels should be applied with timing matched to plant growth, ensuring applied nitrogen is utilised as efficiently as possible.

Nutrient uptake

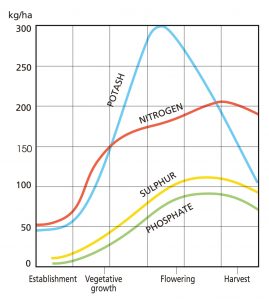

Arable

For arable crops the typical uptake pattern of major nutrients is shown in figure 1. Relatively small amounts of nutrient are required during the establishment period, but such supplies are vital to the development potential of the crop. Daily uptake increases dramatically during vegetative growth and restriction of nutrient supply at this stage can critically affect final yield and product quality such as grain sample, tuber size and numbers, sugar content etc. Peak uptake for potash is around flowering time for most combinable crops and at the end of the growing season for root crops. Peak uptake for nitrogen and phosphate coincides with the end of season.

Typical potash uptake and removal for high yielding crops

Plants must be able to take up nutrients when required at the rate to match potential growth. The total supply must provide for peak uptake rather than just the quantity removed at harvest. These can be very different especially for potash.

| Peak uptake | Removal | Top-up requirement* | |

| kg/ha | |||

| Cereals – grain only | 310 | 45 | 30 |

| Cereals – grain & straw | 310 | 85-130 | 70-120 |

| Oilseed rape | 375 | 40 | 30 |

| Potatoes | 440 | 290 | 280 |

| Sugar beet | 400 | 100 | 90 |

| Peas, beans | 190 | 50 | 40 |

| Source: AHDB Nutrient Management Guide (RB209) | |||

| *The top-up requirement is the amount of potash required following biosolids (digested cake) applied at typical field rates, supplying 12 kg/ha available potash. | |||

Grass and forage crops

With grazing, the livestock are continuously recycling nutrients back to the soil via dung and urine so replenishment needs are low. However, hay and silage are similar to the arable situation – but more so! Grassland conservation removes the whole crop, often several times a season, thus both uptake and removals of potash can be very large.

Typical K2O removal in cut grass forage crops

| Removal | Top-up requirement* | ||

|

|

|

Kg/ha | |

| Silage | 1 cut | 140-165 | 130-160 |

| 2 cuts | 230-275 | 220-260 | |

| 3 cuts | 280-340 | 270-230 | |

| Maize | 180 | 170 | |

| Fodder beet | 340 | 330 | |

| Wholecrop | 160 | 150 | |

| Hay | 90 | 80 | |

|

Source: AHDB Nutrient Management Guide (RB209) |

|||

|

*The top-up requirement is the amount of potash required following biosolids (digested cake) applied at typical field rates, supplying 12kg/ha available potash. |

|||

Potash application timing

Grass

| Reseeding | Apply at or before establishment |

| Grazing only | Any time except during March-May spring flush |

| Cutting | Apply recommended rates before each cut up to a maximum of 90 kg/ha. Apply amounts above this in the previous autumn/winter. For single cut systems potash can be applied at any time over winter or in early spring of the following season. |

Winter & Spring sown crops

| Timing | |||

| Soil K | Spring sown (except roots) | Winter sown | |

| Under 100 mg/l | |||

| Light soils | between January and sowing | up to 50kg/ha in seedbed, remainder spring | |

| Other soils | between autumn and sowing | all in seedbed | |

| 101-150mg/l | Any time | ||

| Over 150mg/l | Any time (rotational applications possible) | ||

| Note: recommendations in this leaflet relate to ammonium nitrate exchangeable potassium and the standard Index classification of results. |

|||

Potatoes

| Apply up to 190 kg/ha in the seedbed |

| Apply the remainder earlier in the spring or in the previous autumn/winter (after year-end for very sandy soils) |

Sugar Beet, Fodder Beet, Mangolds*

| Soil K | Timing |

| Under 100 mg/l | Apply in Jan/Feb after ploughing |

| 101-150 mg/l | Apply before ploughing, except for 40 kg/ha (30 units/acre) of K2O – to be applied immediately after drilling |

| Over 150 mg/l | Apply before ploughing |

| If more than 190 kg/ha of potash is required some should be applied in autumn or earlier in the rotation. | |

| *Sodium (salt) is also needed for these crops except where soil Na is more than 40 mg/l as in some organic soils and fen silts. Normal requirement is 200 kg/ha Na2O which is equivalent to 150 kg/ha Na. Salt should be applied at least 3 weeks pre-drilling. | |

Additional potash requirements for crops receiving biosolids

Typical applications of biosolids (digested cake) supply just 12 kg/ha available potash, which is only a small proportion of the total requirement for most crops, highlighting that potash applications following biosolid applications should not be overlooked.

18-38 kg/ha available SO3 is also supplied following a typical application of biosolids, based on the assumed 10-20% availability seen in recent research. However, sulphur from autumn applications may be lost via overwinter leaching. The quantity leached will depend on soil type and overwinter rainfall and is likely to be higher on light textured soils in high rainfall areas.

Fertiliser policy should be tailored to individual situations taking into account: rotation, crop grown, yield, treatment of residues such as straw, soil type and soil fertility level. Refer to other PDA leaflets or to the AHDB Nutrient Management Guide (RB209) for precise guidance for individual crops. Check soil nutrient status every 3-5 years by soil analysis.

Conclusion

The application of biosolids to agricultural land makes a useful contribution to the recycling of nitrogen and phosphate, and completes natural carbon cycles. However, biosolids are seriously imbalanced nutritionally because of their low potash content. Where they are used additional potash is required and there is frequently only a need to apply a straight potash fertiliser to balance the N and P in the biosolids. Serious soil fertility and crop yield problems will usually arise if this balancing potash is omitted. Potash is firmly held in most soils so there is considerable flexibility in timing the applications of this essential nutrient.